Hybrid light-sensor and GPS-guided tracker with AI decision layer for improved energy harvest in grid/off-grid installations

A hybrid solar-tracking system designed to maximize PV energy capture by combining a local light-sensor array (LDRs), GPS-based solar-positioning, and a lightweight AI decision module. The system supports robust operation in off-grid and networked installations, balances energy gains against actuator energy costs, and includes fault-tolerance and fallback strategies. Key technical elements:

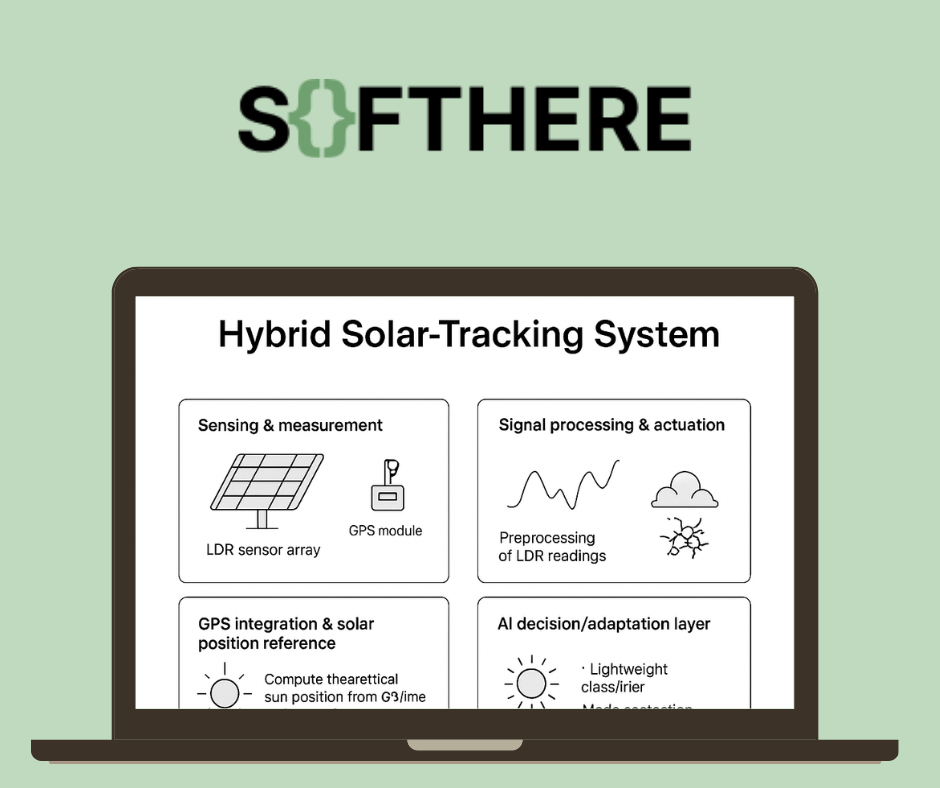

Sensing & measurement

LDR sensor array deployed around the panel to measure local irradiance gradients for accurate directional feedback.

GPS module for geolocation and accurate time reference to compute theoretical sun azimuth/altitude (Solar Position Algorithm).

Optional sensors: spectral/irradiance sensor, panel temperature, voltage/current monitoring (IV).

Signal processing & actuation

Preprocessing of LDR readings (smoothing, outlier rejection, hysteresis) to avoid oscillatory behavior.

Actuators: servo or stepper motors (single-axis or dual-axis) with fine movement control.

Control strategy: PID loop with hysteresis and deadband to minimize unnecessary movement and wear.

GPS integration & solar position reference

Compute theoretical sun position from GPS/time as base reference.

Fuse GPS-derived target with LDR feedback for local optimization and correction of mechanical alignment errors or local shading.

AI decision/adaptation layer

Lightweight classifier (e.g., small CNN, SVM, or decision tree) to infer sky conditions (clear/partly-cloudy/overcast) from irradiance patterns.

Mode selection: full tracking, stepped/economy tracking, or hold/stationary for heavy cloud to reduce actuator use while maximizing net energy.

On-device fault detection to identify failed sensors and apply compensatory strategies.

Power management & off-grid operation

MPPT-enabled energy flow with battery management.

Energy-aware actuation policy: move only when net energy gain justifies actuator power.

Backup power (UPS/battery) to allow tracking during short outages.

Robustness & field durability

Environmental protection (IP-rated enclosures), surge protection, and wind-load considerations.

Fallback behaviors: when GPS or LDR array fails, either switch to theoretical tracking or safe stowed position.

Expected performance & KPIs

Energy gain: typical improvements of ~25%–35% over fixed-mount installations (empirical).

Metrics: pointing accuracy (deg), energy harvest gain (%), actuator duty cycle, response latency, MTBF for mechanical parts.

Implementation recommendations

Controllers: Arduino for sensor/actuator real-time tasks; Raspberry Pi for higher-level processing, AI inference, and network communications.

Communications: I2C/SPI for sensors, UART for GPS, MQTT/HTTP for remote telemetry.

Software tools: SPA (solar position), Kalman/median filters, TensorFlow Lite or scikit-learn for lightweight models.

Testing & field validation

Site-specific calibration and baseline measurements.

Comparative trials: fixed vs LDR-only vs GPS-assisted vs AI-adaptive across weather regimes.

Financial analysis (CAPEX/OPEX) and payback time computations.

Extensions

Fleet management dashboard (IoT) for multi-array monitoring, alerting, and aggregated analytics.

Integration with microgrids and smart-city platforms; weather-forecast informed scheduling; cloud-based ML retraining for improved classification.